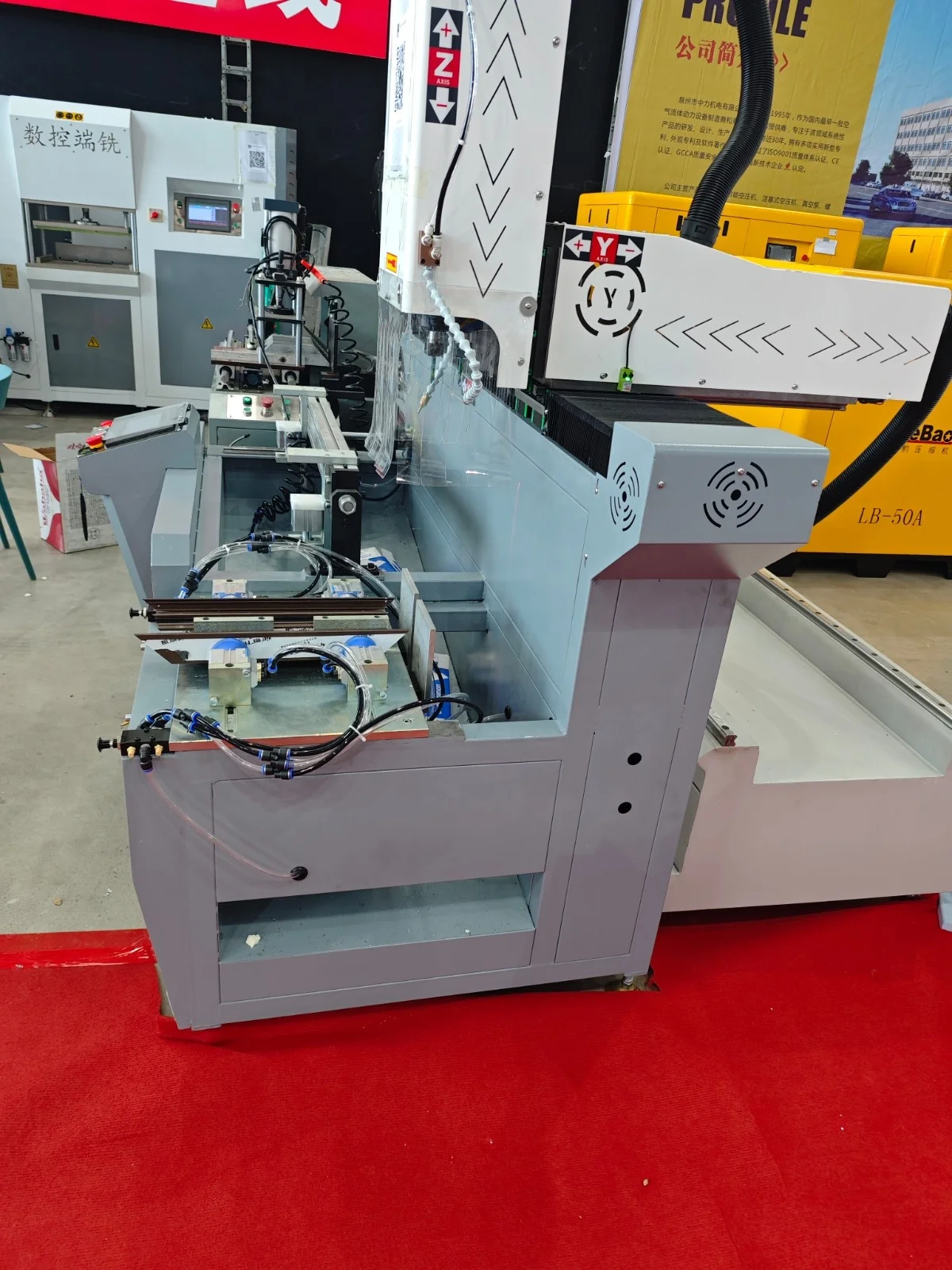

High Quality CNC Router Milling and Drilling Machine for Aluminum Window Door Making

Briefing

The product is a High-Quality CNC Router Milling and Cutting Machine. This machine is designed for efficient and precise milling and cutting of various materials using CNC technology.

Key Specifications

- Type: CNC Router Milling and Cutting Machine

- Material: Steel

- Operation: Automatic

- Power: Varies based on model

- Voltage: 220V/380V

- Cutting Capacity: Varies based on model

- Rotary Speed: Varies based on model

- Weight: Varies based on model

- Dimensions: Customizable

- Control: Electric with CNC control system

Applications

- Woodworking: Ideal for milling and cutting wood in various woodworking projects.

- Metalworking: Suitable for milling and cutting metal in various metalworking projects.

- Plastic and Composite Materials: Can be used for milling and cutting plastic and composite materials.

- Customizable: Can be customized for different sizes and specifications.

Summary

This high-quality CNC router milling and cutting machine offers a powerful and efficient solution for milling and cutting various materials. It is designed for automatic operation with a high-precision CNC control system, making it suitable for use in various industries such as woodworking, metalworking, and plastic processing. The machine is customizable in terms of size and specifications, providing flexibility for different projects. Its durable construction and advanced control features ensure reliable performance.

1. The spindle adopts an air-cooled electric spindle with a power of 9KW and a maximum speed of 24000 rpm, with high precision, good safety and high reliability.

2. The German PA industrial CNC system is equipped with professional CAD-CAM programming software, with powerful functions, simple operation and high efficiency.

3. Can be equipped with 6 tool magazines, which can realize continuous and uninterrupted processing.

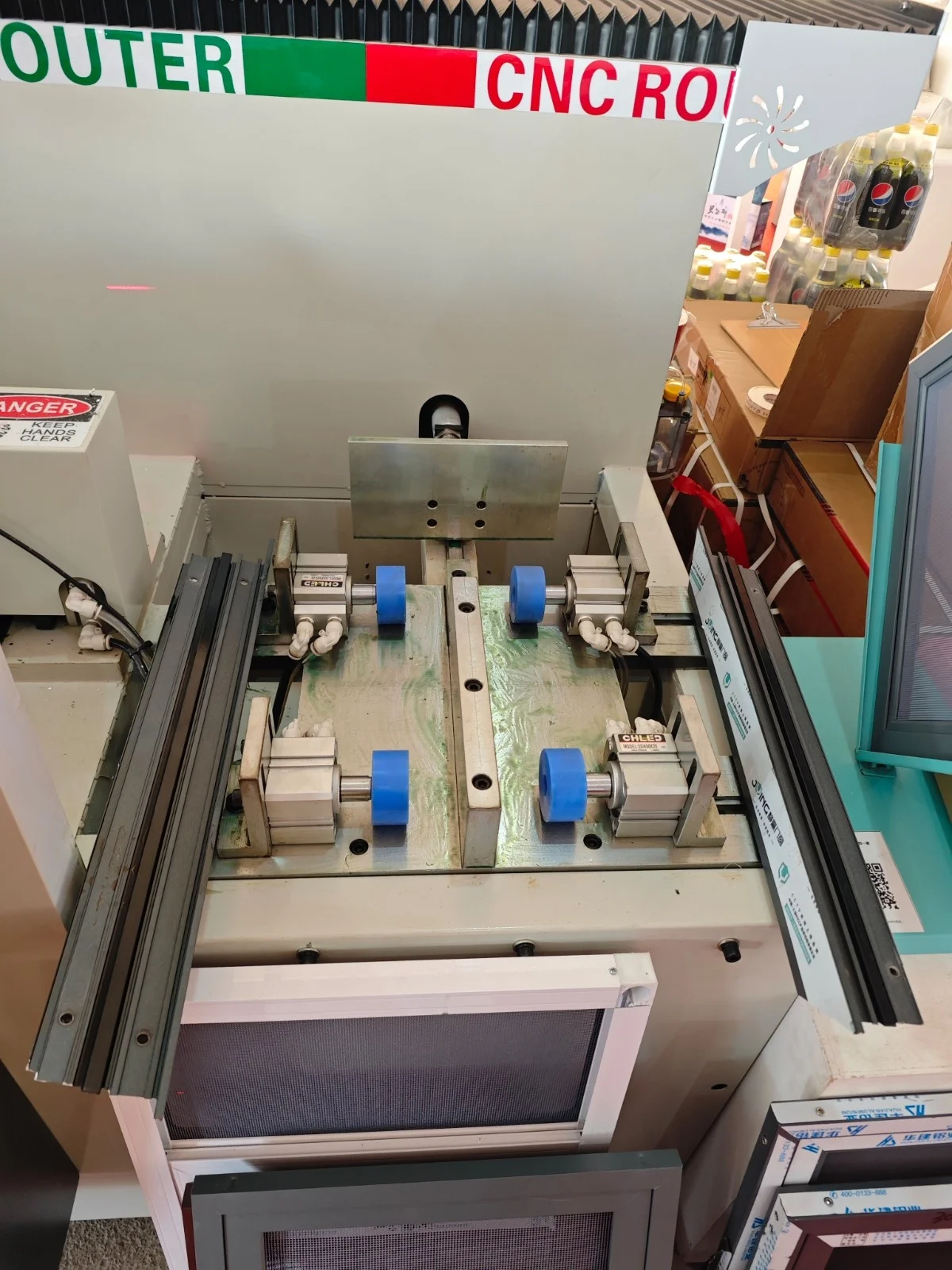

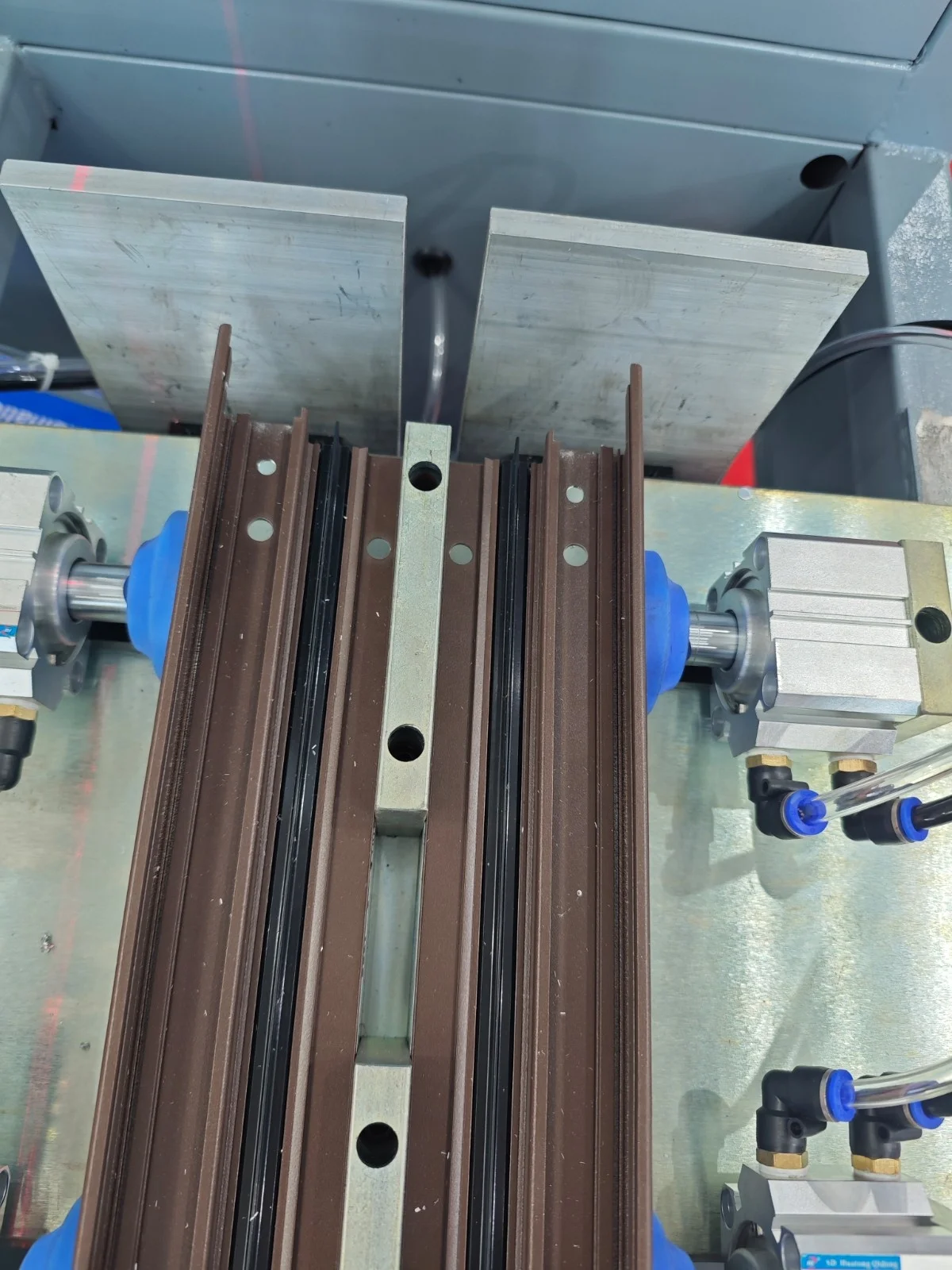

4. The worktable is turned 180°, -90°~0°~+90°, and the profile can be processed on three sides by one clamping. When processing deep through holes (special-shaped holes), deep hole processing can be realized by turning the worktable, which improves efficiency and good quality.

5. The automatic oil supply system is adopted, and the tool adopts a system-controlled spray cooling device.

6. The main components of the machine tool are made of steel, all of which have undergone vibration aging stress relief treatment to ensure stable operation of the machine tool.

|

WSZ-CNC-3200 (single head)

|

WSZ-CNC-1500 ( double head)

|

WSZ-CNC-1200 (single head)

|

WSZ-CNC-800 (single head)

|

|

|

Power Supply

|

380V 50Hz

|

380V 50Hz

|

380V 50Hz

|

380V-50Hz

|

|

Input Power

|

9kW

|

9.5kW

|

3.5kW

|

3.5kW

|

|

Rotating Speed

|

18000rpm

|

18000rpm

|

18000rpm

|

18000rpm

|

|

Air Pressure

|

0.5-0.8MPa

|

0.5-0.8MPa

|

0.5-0.8MPa

|

0.5-0.8MPa

|

|

X-axis Travel

|

3200mm

|

1500mm

|

1200mm

|

800mm

|

|

Y-axis Travel

|

400mm

|

300mm

|

300mm

|

300mm

|

|

Z-axis Travel

|

300mm

|

280mm

|

280mm

|

280mm

|

|

Processing Range

|

130x150mm

|

110x150mm

|

110x150mm

|

110x150mm

|

|

Overall Dimension

|

4000x2000x2800mm

|

2000x1800x2300mm

|

1650x1500x2000mm

|

1400x1500x2000mm

|