Tissue Toilet Paper Making Machine Without Core Toilet Paper Rewinding Machine

Briefing

This tissue toilet paper making machine is designed for producing high-quality toilet paper rolls. It features advanced technology and automation to ensure efficient and consistent production.

Specifications

- Standard Width of Jumbo Roll: 1390mm or 1850mm

- Daily Capacity: >12 tons/day (8 layers, 13.5 g/㎡, 24 hours)

- Tissue Paper Layers: 2-4 layers

- Tissue Paper Grammage: 2 layers: 13.5-18 g/㎡ per layer; 3-4 layers: 11-15 g/㎡ per layer

- Tissue Folding Capacity: 13 strips/min

- Production Capacity: 12 strips/min or 110 m/min

- Control System: PLC control with large screen HMI operation

- Drive System: Servo & variable frequency drive

- Technology: Mechatronics with automatic detection and adjustment

Key Features

- High Automation: The machine can complete the entire process of tissue paper embossing, folding, counting, cutting, and packaging with a high degree of automation.

- Efficient Production: Capable of producing over 12 tons of tissue paper per day.

- Advanced Control System: Equipped with PLC control and large screen HMI operation for easy monitoring and control.

- High-Quality Output: Produces high-end facial tissues with consistent quality.

- Versatile: Suitable for producing various types of tissue paper products.

Applications

- Household Paper Processing: Ideal for producing high-end facial tissues and other tissue paper products.

- Commercial Use: Suitable for large-scale production in tissue paper manufacturing plants.

- Industrial Use: Can be used in industries requiring high-quality tissue paper products.

Summary

The tissue toilet paper making machine is a highly efficient and automated solution for producing high-quality tissue paper products. With its advanced technology and high production capacity, it is an excellent choice for household paper processing enterprises and large-scale manufacturing plants.

New Design Automatic Toilet Paper Roll Embossed Rewinding Machine Small Toilet Tissue Paper Making Machine

|

Machine Model

|

1575/1880//2400/3000/S3000

|

|

Paper Width(mm)

|

Max 1750mm/2200mm/2400mm/3000mm/3050mm

|

|

Paper Diameter(mm)

|

φ1150mm(Please Specify)

|

|

Paper Core Inner Diameter

|

φ76mm(Please Specify)

|

|

Product Diameter

|

φ50mm-180mm

|

|

Paper Backing

|

1-4layer,general chain feed or continuously variable transmission feed paper

|

|

Punch

|

2-4 Knife, Spiral Cutter Line

|

|

Hole Pitch

|

Positioning of Belt and Chain Wheel

|

|

Control System

|

PLC Control, Variable Frequency Speed Control, Touch Screen Operation

|

|

Product Range

|

Core Paper, Non Core Roll Paper

|

|

Drop Tube

|

Manual, Automatic(Optional)

|

|

Non core roll paper

|

automatic core pulling

|

|

Production Speed

|

80-200m/min

|

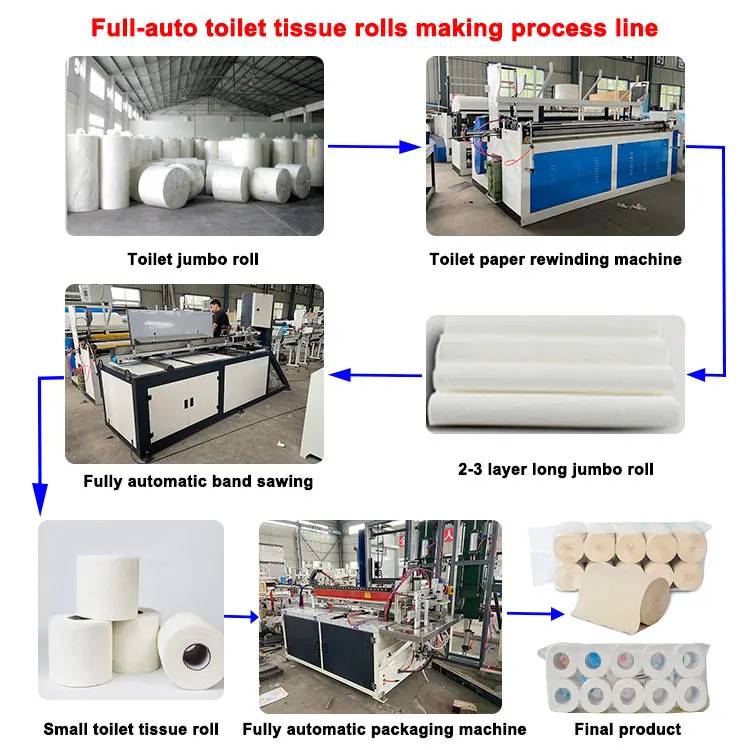

Working Principle

Four-roller automatic feeding →synchronous conveying →embossing →punching →automatic winding →cutting→ packing →sealing.

1. Rewinding—The main purpose of the toilet paper rewinding machine is to process the large shaft paper into a long strip of toilet paper roll.

2. Cut the paper—The long piece of toilet paper cut by the paper cutter is cut into semi-finished products of the length

required by the customer.

3. Packaging—Packaging can be packaged in a packaging machine or manually wrapped, and the semi-finished products of the toilet paper are packaged and sealed by a sealing machine.